R. Dr. Francisco Sá Carneiro

Zona Industrial de Bouro - Letra C

4740-010 Esposende, Portugal

Industrial Glass Protect

Soiling mitigation coating to protect from soiling and reduce cleaning time

Industrial Glass Protect is a ready-to-use coating for soiling mitigation and performance enhancement specially developed and certified for solar panels.

It combines the hydrophobic with the antiadherent properties, reducing the soiling’s adhesion to the modules and keeping your solar panels cleaner between cleanings by improving the self-cleaning properties on wet environments. Its properties also make the next cleaning easier and reduce light reflection on rainy days by quickly removing the water from the surface.

The hydrophobic coating on the Industrial Glass Protect was designed to be applied on a factory level and under controlled environment.

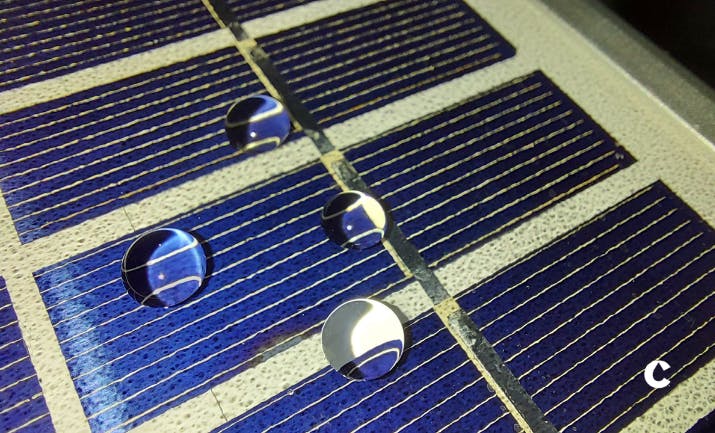

Effect of the hydrophobic coating from the Industrial Glass Protect solution

Solar panel water repellent due to IGP

Glass unprotected with IGP - no effect visible

Glass protected with IGP - hydrophobic effect visible

Certified for solar panels by ÉMI-TÜV Sud

The international laboratory ÉMI-TÜV Sud, recognized by their services of certification of solar panels, certified the IGP as safe for solar panels. This certification assures that the use of the IGP does not damage the panel’s components (e.g., aluminum frame, anti-reflective coating and silicone seals), does not interfere with the light transmission and that the antiadherent coating is effective in the reduction of the dust buildup and adhesion.

Approved by JA Solar

The Industrial Glass Protect is approved by JA Solar, one of the biggest PV manufacturers in the World, for use on their modules without voiding the warranty

Available formats

- 1L Drum

- 2L Drum

- 5L Drum

FAQs

Industrial Glass Protect gives your solar panels a hydrophobic coating, which repels water from your panel, reducing soiling adhesion to your panel, water consumption, and cleaning time in subsequent washings, and thereby increasing energy production.

The Industrial Glass Protect is a product specially developed to be applied in the factory. Make sure the surface of your panel is clean and degreased. Use latex gloves throughout the process to ensure a completely clean and dry surface. Then, apply a fine mist of product on the desired surface, making sure you polish the treated surface with a microfiber cloth or a polishing beret. After polishing the entire surface, do not expose the glass surface to water or any other liquids for at least 1.5 to 2 hours.

To seal the solar glass, after having the entire surface thoroughly cleaned, you must apply a fine mist of product spraying it between 30 cm to 40 cm.

Prevent the product from drying on the surface without being polished. It is advisable to apply in smaller areas in case of higher ambient temperatures.

ChemiTek recommends applying approximately a volume of 5-10 mL/m2. For large surfaces, application using a HPLV spray gun is recommended.

After treating the surface, do not expose the glass surface to water or any chemical solution for at least 1.5 to 2 hours.

No, this solution is ready to use. Just apply it directly to the glass/non-porous surface you want.

In case of doubt contact us.

Once the Industrial Glass Protect has been opened, it must be used within 12 months to ensure the product's characteristics.

Industrial Glass Protection has thoroughly tested for both durability and easy to clean functionality. The durability test was carried out to simulate a lifetime of 5 years on exterior use.

A good cleaning procedure is necessary in order to achieve the desired stability over time.

Yes, a new glass also must be prepared. However, since there are no incrustations present, the glass only needs to be cleaned and degreased.

In case of over-application of the product, the solution is simple: the glass surface will look greasy, and it will be necessary to remove the excess product with a microfiber cloth. After removing the excess, use a (new) clean microfiber cloth to polish the surface until the product is no longer visible.

Do not apply at temperatures below 5°C or above 30°C; the ideal application temperature is between 15 and 25°C. Low temperature will delay the curing of the coating and high temperatures lead to accelerated evaporation of the product during application.

When you notice the coating has reached the end of its life and is no longer performing as expected, you can reapply the IGP solution. Simply repeat the process as you did the first time. It is not necessary to remove the previous coating before reapplying IGP.

Yes, Industrial Glass Protect is not a cleaner, it is a hydrophobic coating, which helps keeping the surface cleaner for longer by making it harder for dirt to build up. However, keep in mind this product does not fully eliminate the need for cleaning your solar panels.

The correct application of the coating guarantees a lifespan of up to 5 years.

ChemiTek recommends that a glass surface protected with IGP should be cleaned with a microfiber cloth and, if necessary, a mild, non-abrasive, neutral pH detergent. NEVER use abrasive and/or highly acidic or alkaline detergents, as it will greatly shorten the life of the coating. If your area has hard water and causes a lot of limescale deposits, we suggest using pure white vinegar diluted in water in a 1 to 5 ratio (200mL of vinegar for every litre of water) to clean the glass.

Yes, this product is non-abrasive and environmentally-friendly, being developed to apply both indoor and outdoor. When applied inside, the ventilation of the space must be guaranteed.